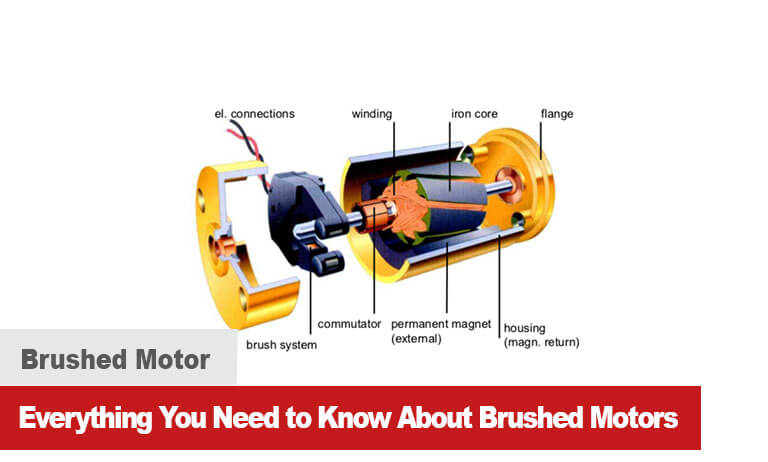

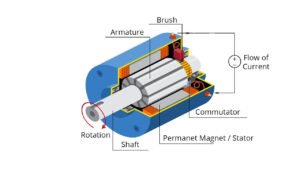

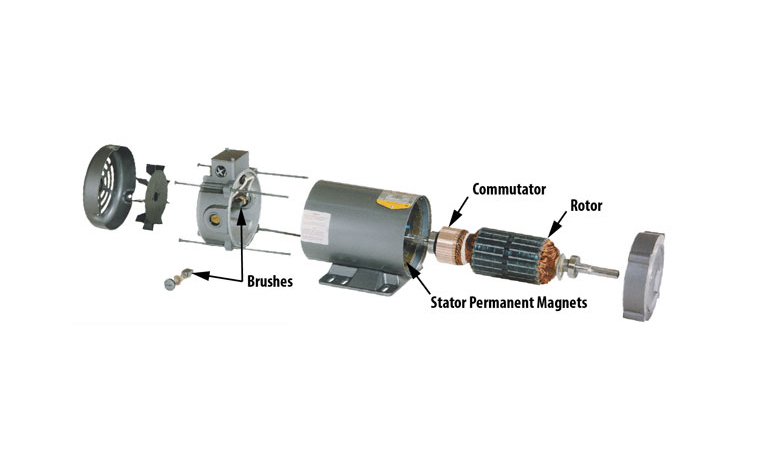

If you’ve ever seen sparks coming from a power drill’s motor cooling vents, you’ve seen electric Brushed Motors in action. The arcing is caused by electricity being carried from the stator, which is the nonrotating component of the motor, to the armature, which is the spinning part. Brushes are the parts of an electric motor’s stator that conduct the current to the rotor.

When electricity is applied to the electromagnet in the armature, a magnetic field is created that attracts and repels the magnets in the stator. The armature rotates in a 180-degree circle. To maintain the electromagnet spinning, the poles must be swapped. The brushes are in charge of polarity shifts. They make contact with the armature’s two rotating electrodes. The magnetic polarity of the electromagnet is reversed as it rotates.

By adjusting the operating voltage or the intensity of the magnetic field, the speed and torque may be adjusted to give a constant speed or a speed that is inversely proportional to the mechanical load. (The controller sends current pulses to the motor windings, which govern the motor’s speed and torque.

f you want to know the full range of electric motors, you can read the article on electric motors to learn more about their types and how electric motors work.

A carbon brush is a sliding contact used in Brushed Motors and generators to transport electrical current from a static to a revolving part while assuring spark-free commutation.

A carbon brush can be any of the following: It’s made up of one or more carbon atoms. One or more shunts and terminals are included.

In the operation of electrical machinery, the carbon brush is crucial. We must consider three sorts of parameters in order for it to do its function:

Mechanical

Electrical

Physical and chemical

Brushless motor tools, such as drills, jackhammers, planers, hedge trimmers, and grinders, require them to work properly. Carbon brushes are selected based on the tool’s brand and kind. They are put on the permanent portion of a motor to guarantee that power is transmitted to the rotor as efficiently as possible (the rotating part). They allow for switching without the need of a spark.

These components, which work in pairs, are worn parts that are prone to friction. The slip rings are permanently in touch with the carbon brushes. These graphite components come in a variety of shapes and sizes. They might have a spring, a connection (a wire with a plug), or no brush holder at all. Brushed Motors come in a variety of sizes and forms (often square and rectangular) and may contain grooves to aid in direction.

The drill’s speed is expressed as a percentage of torque, which is determined by the intensity of the magnetic field. Carbon brushes are spring-loaded and fastened to a spring with a plate to guarantee that power is passed smoothly. In certain circumstances, the brushes are held in place by a brush holder with a spring designed to increase force.

Breaker brushes, on the other hand, are used to stop the brushed motor and, eventually, the drill before the graphite substance wears out completely. This is done in order to maintain peak performance.

Brushes that are compatible with portable power tools, such as drills, are normally sold by the manufacturers. The thickness, depth, and breadth of the item are measured in millimeters or inches, respectively. These specs, however, may differ from one manufacturer to the next.

Combining elements

Adding pressure to the combination

Green brushes are fired.

Operational support

Contact:Mr Liu

Mobile:15869109368

Tel:86-571-89967020

E-mail:info@dawopu.com

Address:No151 ,ZiDingXiang Rd, Hangzhou. Zhejiang Province, China