A jet engine turbine blade is the individual component that makes up the turbine section of an aircraft engine. The turbine blades are exposed to the harshest environment in terms of pressure and temperature, while rotating at extremely high speed. The materials of turbine blades are, therefore, difficult to machine, heat-resistant superalloys (HRSAs) with high creep strength, high temperature fatigue strength, and high temperature corrosion resistance. Nickel-based HRSAs such as Inconel and Waspaloy have high thermal properties but, in turn, substantially increases the stresses imposed on cutting tool edges during machining.

To improve machining efficiency and chatter of thin-walled sections

To reduce cutting forces when high-feed milling the blade surface in the axial direction for improved machining efficiency

High-performing cutting tools that maximize 5-axis machines

To maintain high part precision

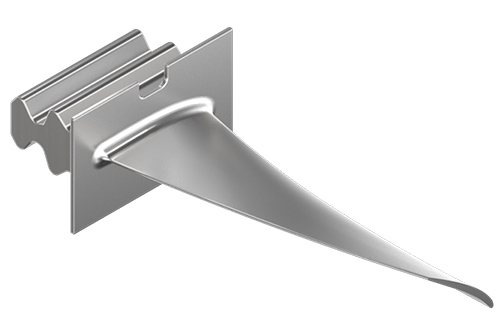

TungMeister-Barrel head offers longer tool life, shorter cycle time, and smoother surfaces, compared with traditional ball nose mills. The cutter’s peripheral cutting edges feature a large curvature radius that facilitates a much greater engagement area between cutter and workpiece than typical ball nose counterparts. Greater engagement area, in turn, enables larger stepovers, which improve metal removal rates and surface finish with less tool wear.

Barrel milling heads are available in three profiles: VBO-short for semi-finishing of general parts, VBO-long for pre-finishing and finishing of die mold parts, and VBN for pre-finishing and finishing of turbine blade surfaces and roots, impellers, blisks, other aerospace parts

Contact:Mr Liu

Mobile:15869109368

Tel:86-571-89967020

E-mail:info@dawopu.com

Address:No151 ,ZiDingXiang Rd, Hangzhou. Zhejiang Province, China